10/20/2016

electronic business card | pt. 4

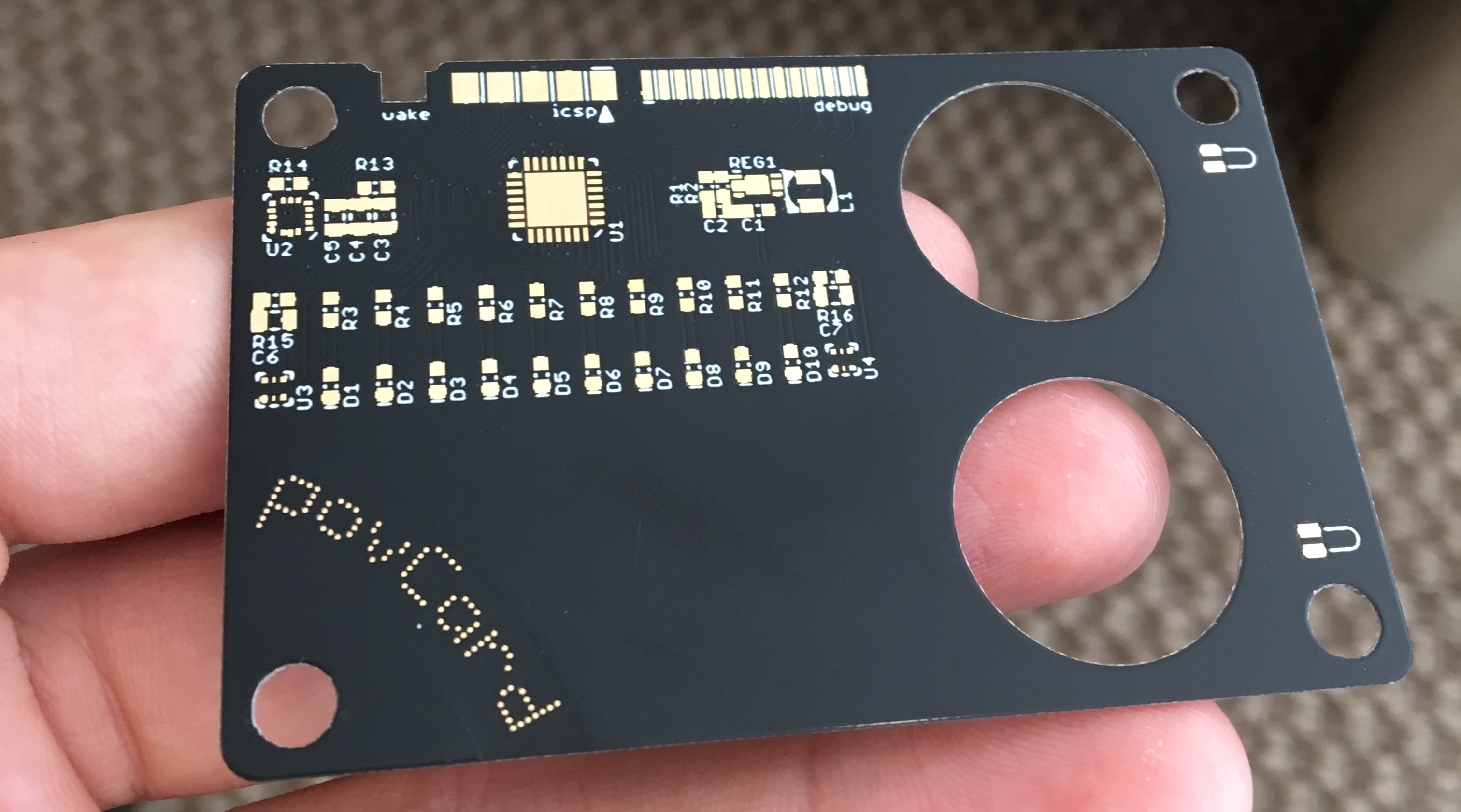

I ordered PCBs last month from two places. Seeedstudio and DirtyPCBs. I've wanted to try these services for a while, and I thought this would be a good test of their capabilities. I placed both orders on the same day, and both orders came to about $75. However, I recieved less boards from DirtyPCBs. Both arrived in the mail on the same day. Although the price on the DirtyPCB boards were slightly higher per board, I would probably order from them next time. The soldermask on the Seeedstudio boards was slighly thinner (and some boards had exposed copper on some traces), and the PCB identification was placed in silkscreen right on the front of the card. The DirtyPCB board had a much more discrete barcode that was laser etched onto the back of the card along the bottom of the board, which was very difficult for me to spot. I hate putting a lot of time into the design of a board for it to be adulturated with some silkscreen from the fabrication house.

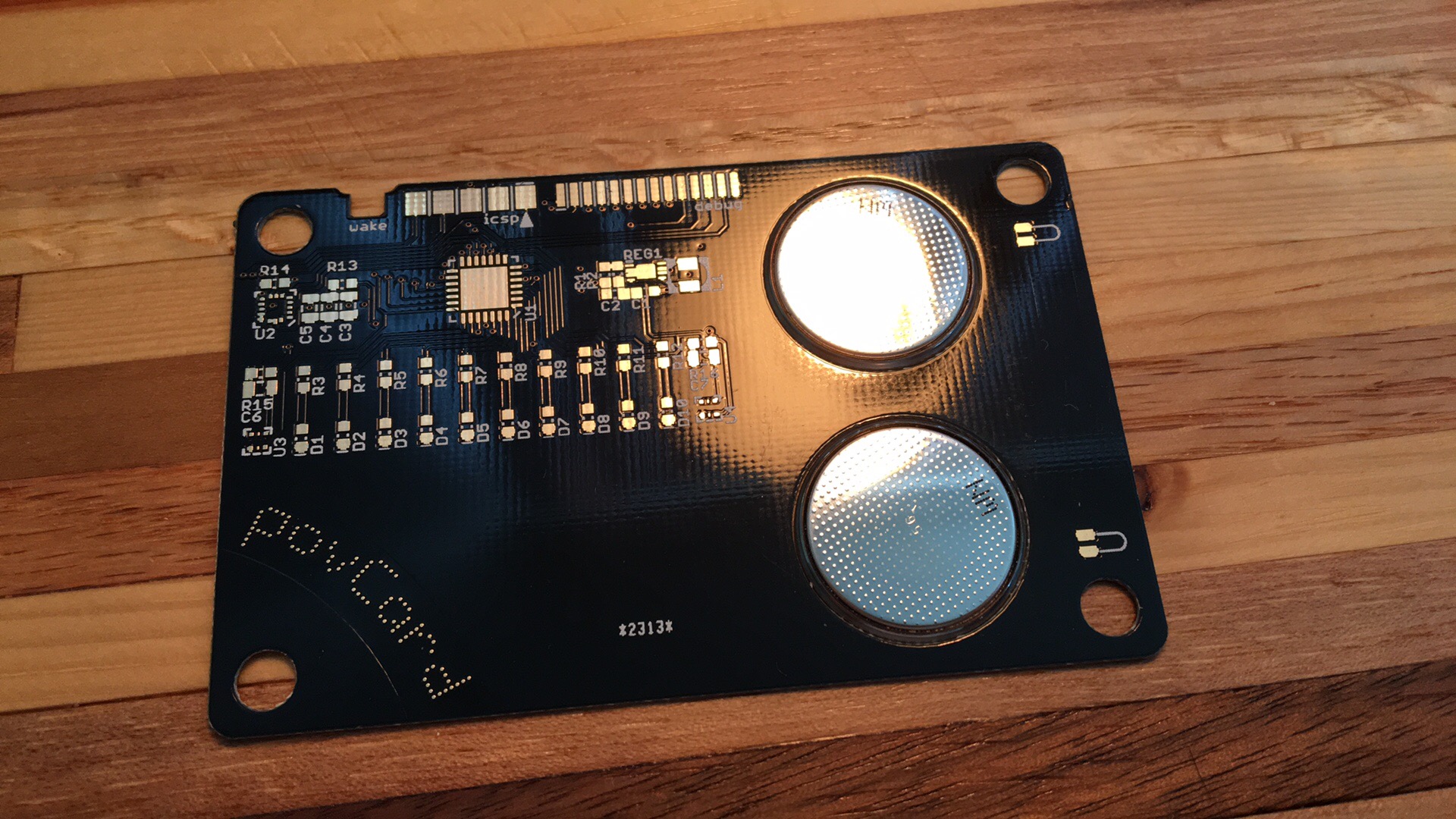

Here's all of the boards I got. I couldn't be happier.

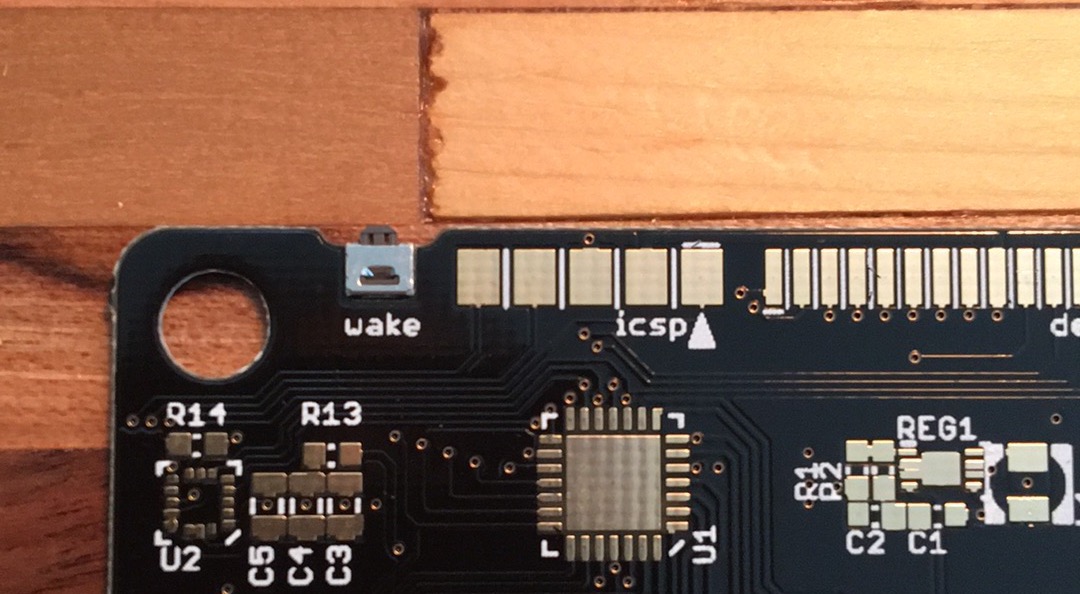

Here's a closeup of how the buttons and batteries fit into the board.

Here's one of the boards from DirtyPCBs, note the lack of the silkscreen identification text on the front.

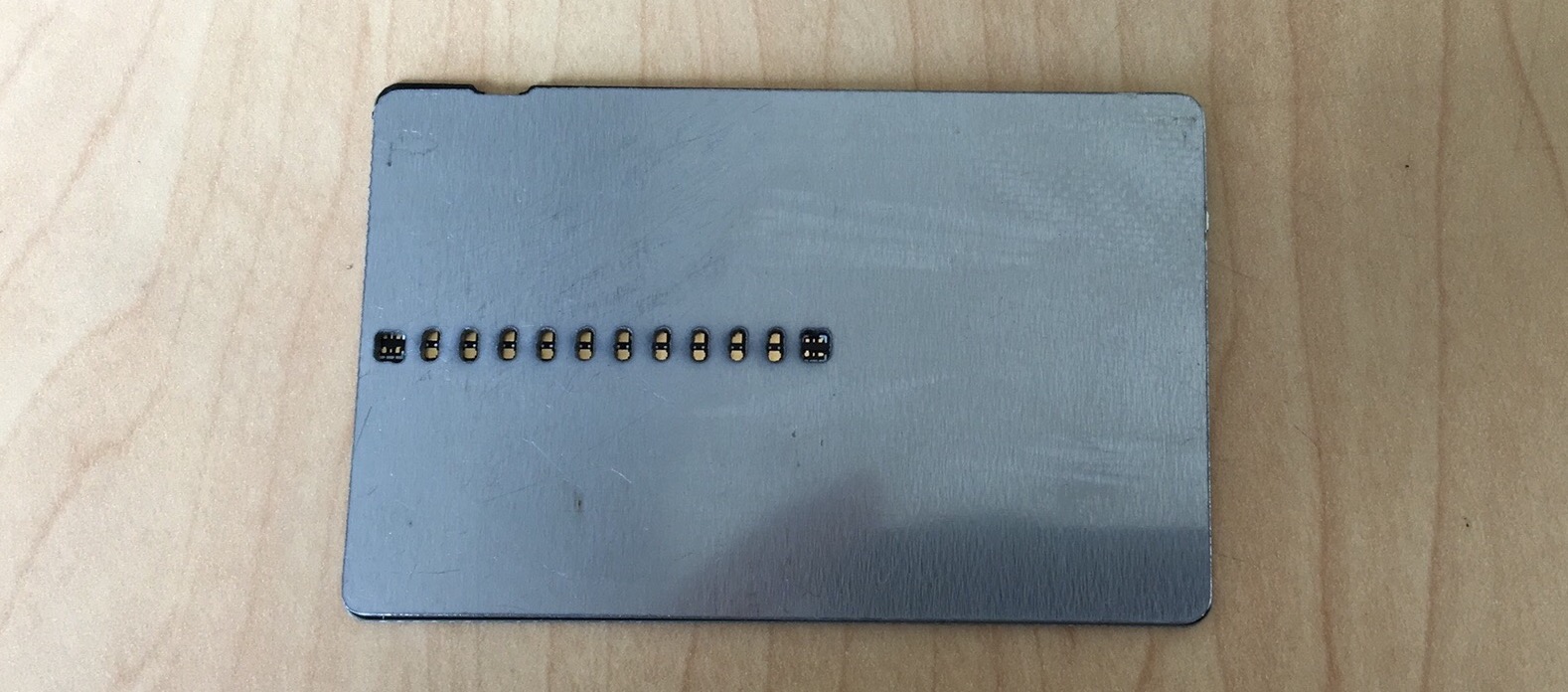

I ordered a piece of stainless steel from McMaster-Carr and cut the outline and holes out of the steel front piece. -- There was some operator error with the waterjet which caused an accidental crash of the cutting nozzle into the metal. I was instructed incorrectly on what to do when the waterjet software prompted to perform a calibration of the 5-axis nozzle (this allows the machine to cut on surfaces that aren't parallel with the cutting bed). After the calibration was finished, we assumed that the reference "home" position was unchanged and told the machine to perform the cuts. However, the calibration process modifies the machine's reference position. The machine jogs to the home position before starting a cut, which caused the nozzle to move vertically into my piece of metal, leaving it slightly bent, which I didn't notice at first.

When the machine was inspected and re-homed, the cut was made. However, since the piece of metal was slightly bent, the cuts were slightly distored. Which is okay for now. It's a bit of a difficult process to get time on the waterjet, so I'll have to come back another time.

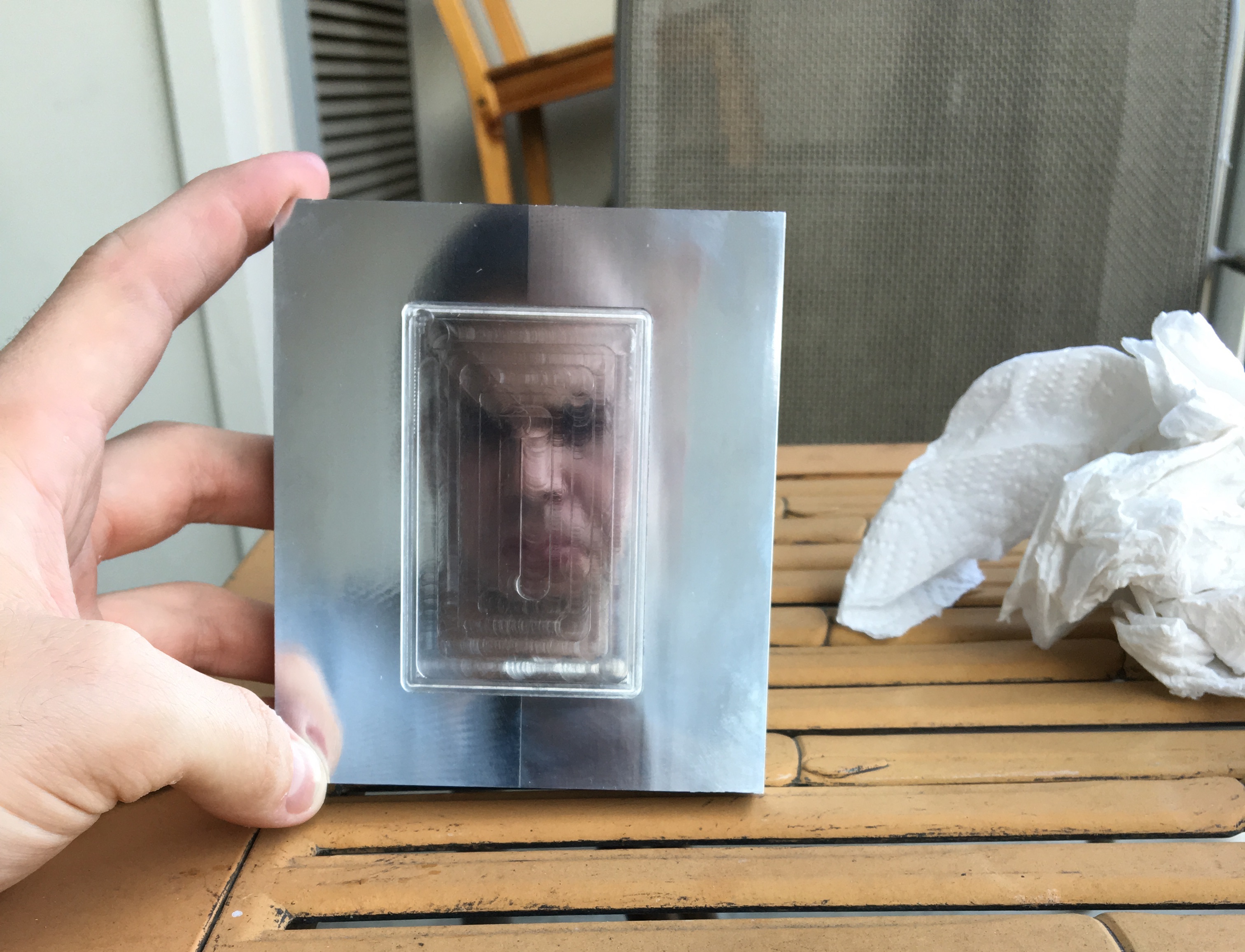

Here's how the steel piece fits over the PCB. Very happy how everything lines up.

The magnets fit perfectly into the holes in the PCB. Here's a video of the PCB snapping onto the steel piece.

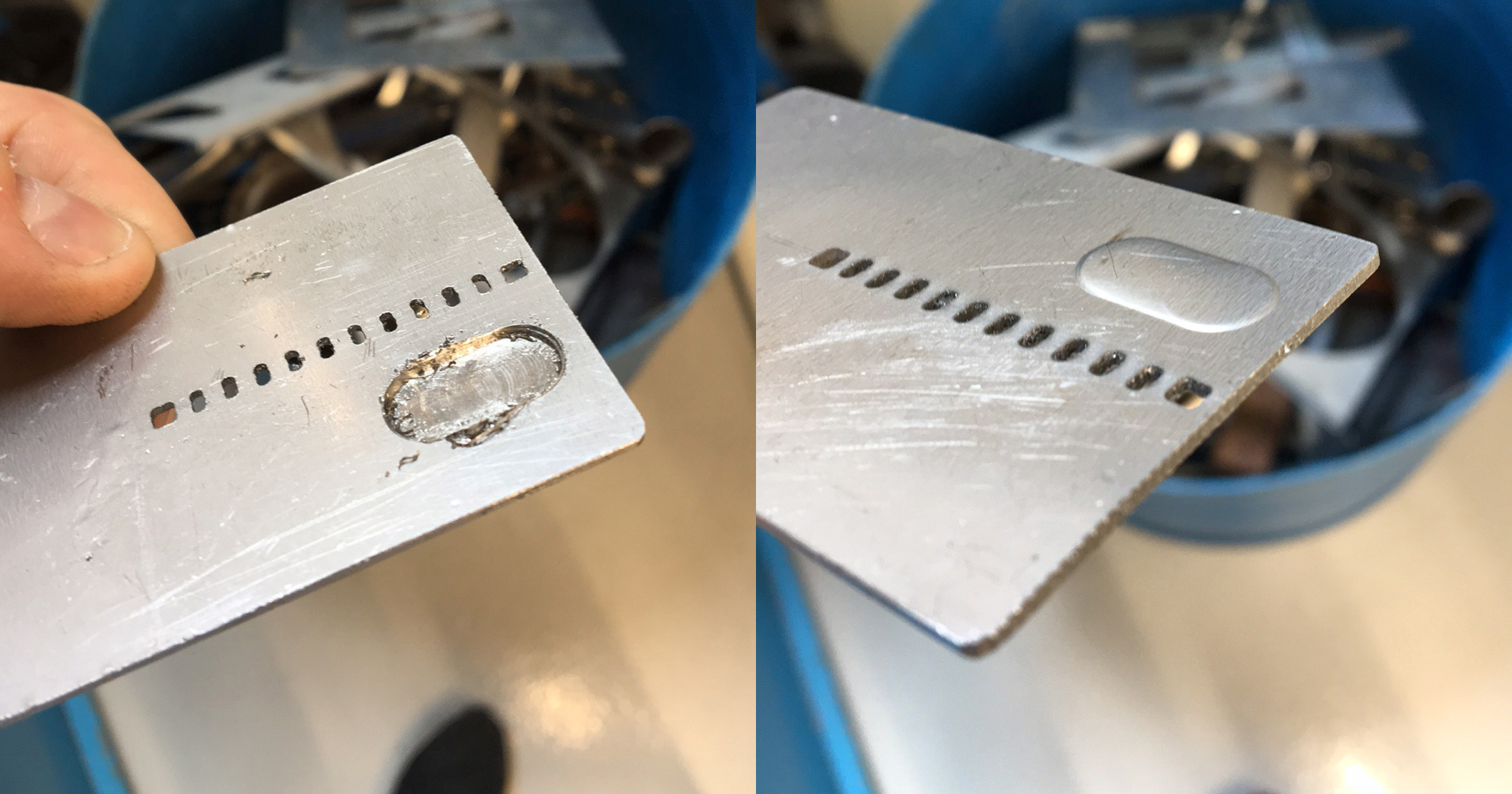

I've ordered a very small endmill to do all of the pockets in the steel piece, but since this piece was already not perfect I thought I'd try and see what I could do with a larger endmill. I was very curious if I was going to be able to mill into the thin piece of metal as far as I needed to. I took a series of cuts, cutting deeper into the material each time. I was getting very excited as the DRO was reading that I had cut about 40 thou deep into my 48 thou thick piece of metal. I took the part out of the mill and my excitement was ruined very quickly as I turned the piece of metal over to find a "bubble" of metal sticking up above the rear surface.

It's pretty clear that as the wall thickness became smaller the rear wall was bent out of the way of the endmill instead of being cut by the endmill. I'm not sure if this can be solved using a sharper and smaller endmill (the ones that are around the shop are fairly abused by students). I asked the shop technicians for some advice and one of them reccomended creating a jig that I can clamp the card down into. That way the back wall has nowhere to go as it is being cut (instead of how I cut it before, which left the rear surface hanging in midair).

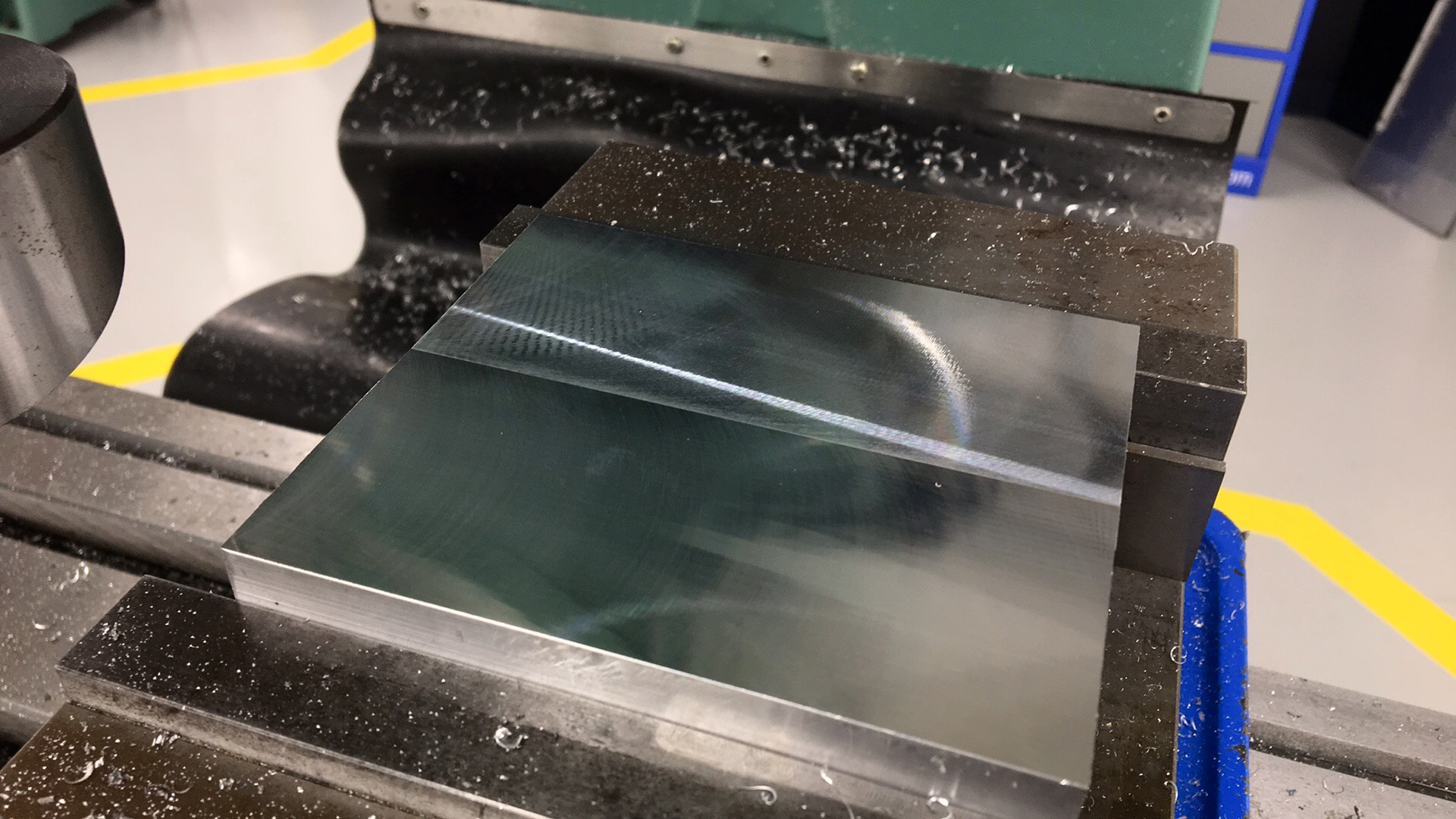

I found a piece of aluminum scrap in the shop, and figured this was a good opportunity to learn how to use a fly cutter.

After the surface was flat (which was kind of an unnessassary operation), I cut a pocket into the middle of the block for the piece of steel to sit in (can you see my face?).

The next steps are to get some new pieces of (unbent) stainless and cut a few more parts out so I have extra. I also need to finish the jig. It needs some holes in it that I can screw some bolts and washers into to clamp down on the steel piece.

10/14/2016

vu meter clock | first prototype

I recently found an old (1980s?) radio/tape player/record player unit sitting in the trash pile behind my apartment. I took it back to my apartment because I thought it would be a treasure trove of electronic and mechanical parts. In taking it apart I scored some motors, pulleys, gears, vintage buttons and bulbs, and a lot of electrical components (though some are usless due to their age). The most exciting components I salvaged were three of these VU meters.

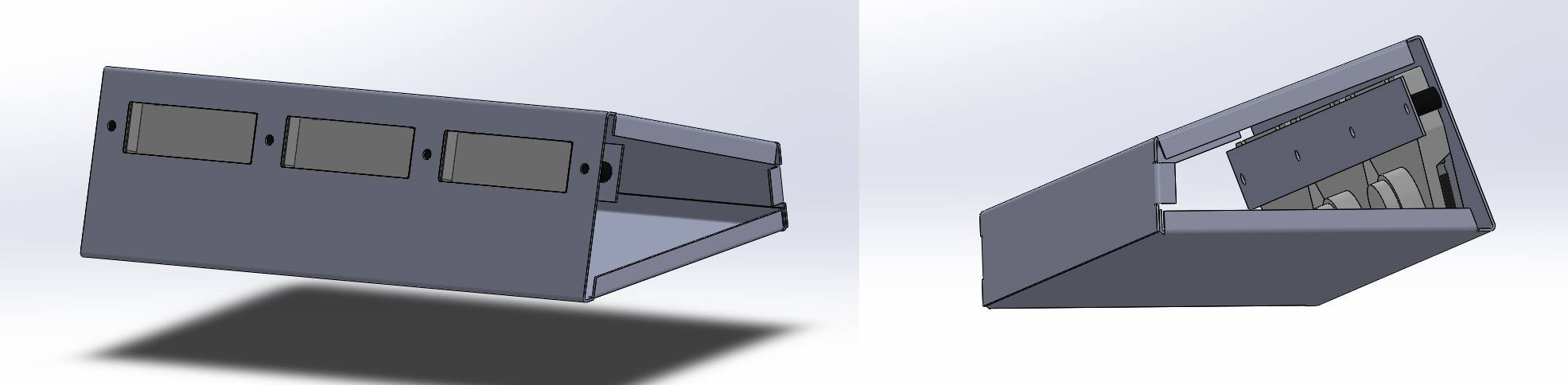

I've been wanting to learn how to use Solidworks' built in sheet metal design tools for a while now as well as learn how to work with sheet metal. I had three of these meters, I figured they'd be perfect to build a clock out of (not that it's a new idea), so I decided to kill two birds with one stone.

I modeled up the meter itself and then just tried various shapes in Solidworks until I was happy with the shape of the enclosure. I settled on this triangular sort of look with the front face sloping backwards a bit, which I thought would look neat as well as make the clock visible when placed on a desk.

I struggled a bit figuring out how I would have all of the bolts go in from the outside and still be able to hold the nut from the inside of the case. I thought for a while about how I would not close up the case while simultaneously preventing me from clamping onto the nuts. I honestly was about to just leave a hole in the bottom until I found these press-in nuts on McMaster-Carr. These are pressed into a hole which makes the teeth on them grab into the surrounding metal. Perfect solution to my problem. I could have also used sheet metal screws, but I was shying away from them.

Here's the water jet cutting out the pieces. I had a bit of a struggle getting the piece of metal to stay flat. I think in the future I'll try and use a sacrificial piece of plywood or MDF to keep the thin metal flat in the bed. If the metal bows up or down while cutting (which can happen easily as the water pressure usually pushes back up as the jet shoots into the water) a slightly distorted pattern is cut.

After the pieces were cut I pressed all of the nuts into the sheet metal. When bending the metal on the brake, I ran into some problems turning the digital representation (which has perfect bends) into a physical one. The main problem was that the main piece bent back onto itself, which made it impossible to make the last bend without the piece running into the brake. Another problem I had was the brake running into the press nuts, which made it hard to get an even bend.

I ended up kind of completing the final bend by hand, just to say I sort of finished it. But the result wasn't pretty.

To hold the meters in I was planning on using some spacers but couldn't find any of the right length. They needed to be as deep as the meters so that the bar could go across the back of the meters but still be attached to the front. You can see this in the photos of the 3D model above. I couldn't find any spacers that were the correct length, so I thought I'd try making some on the lathe. I bought some delrin rod and cut some small spacers. They turned out fine, the flange is due to the parting tool. I was going to clean these up but I'm going to redesign the enclosue so that it doesn't require the spacers, so there's no reason to now.

I do want to install some LEDs inside the case to backlight the meters, here's what that might look like.

The last issue I found with this design was that the clamping plate that I desnged to hold the meters in blocks almost all of the backlight from reaching the meter, so I'll have to redesign the clamp so that it grabs at a different location. Not much force is needed, the clear cover on the front of the meter fits pretty snuggly in the holes of the enclosure, so the clamp is just for extra security.

In order to make any of the parts that I need to complete the business card, I needed to be able to use the machine shop that's available to Georgia Tech students to use. I've been an avid consumer of YouTube machining channels for last year or two, so it was awesome to finally get some hands on time with the mill and lathe.

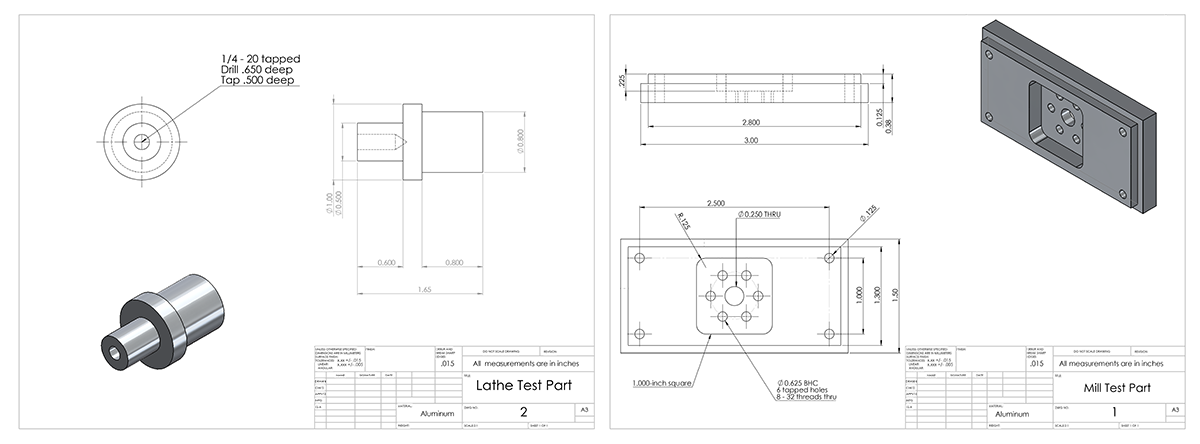

The class was split into two individual three hour sessions that were a week apart. The first class was lathe training and the second class was mill training. We also received some training on the vertical and horizontal band saws. After each class we were given a technical drawing of a part to create on the machine that was covered. To receive certification to use the machine shop, each part had to be made and checked off by an administrator.

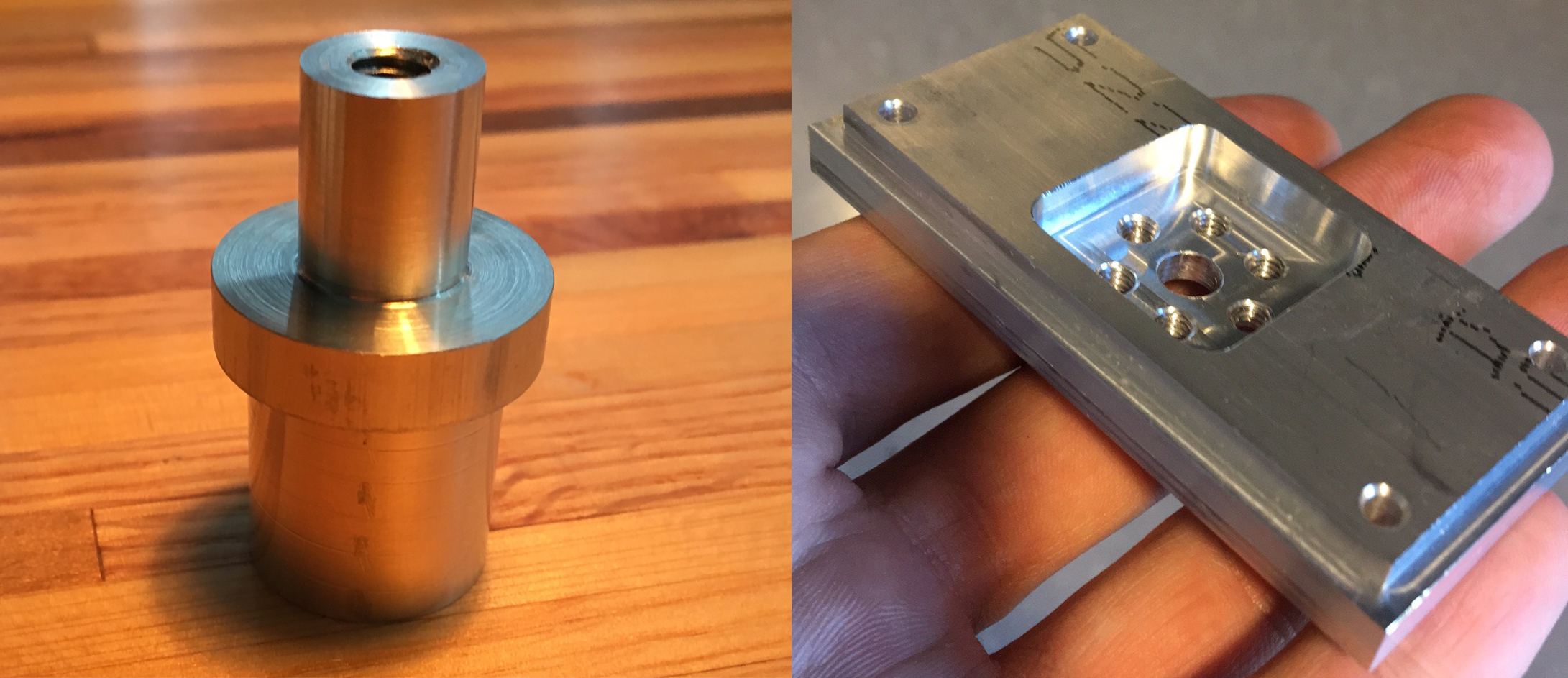

Here are the parts we had to make.

The lathe training focused on manual lathe techniques using the DRO. We learned how find a reference and how to dimension cuts. We also learned how to set the gearing up to do the automatic feed to make a cleaner surface finish. -- The mill training was much more fun. Most of the traditional knee mills in the shop are two-axis CNC controlled with a three-axis digital readout. The interface allows for programming of milling operations. The software keeps track of when the Z axis must be moved, and prompts the operator to move the tool up or down manually before continuing.

We were taught about some of the basic parts of the knee mill: when to use a collet chuck or a drill chuck, how to lock the quill, and how to use the powered draw bar. We were also taught how to use an edge finder, the difference between traditional and climb milling, and the basics of using the ProtoTrak CNC software/DRO installed on the mill. Overall, pretty basic stuff, but enough to make a fair amount of complex parts on the mill.

Here's a pocket being milled into the part I had to make.

Here are my completed parts.

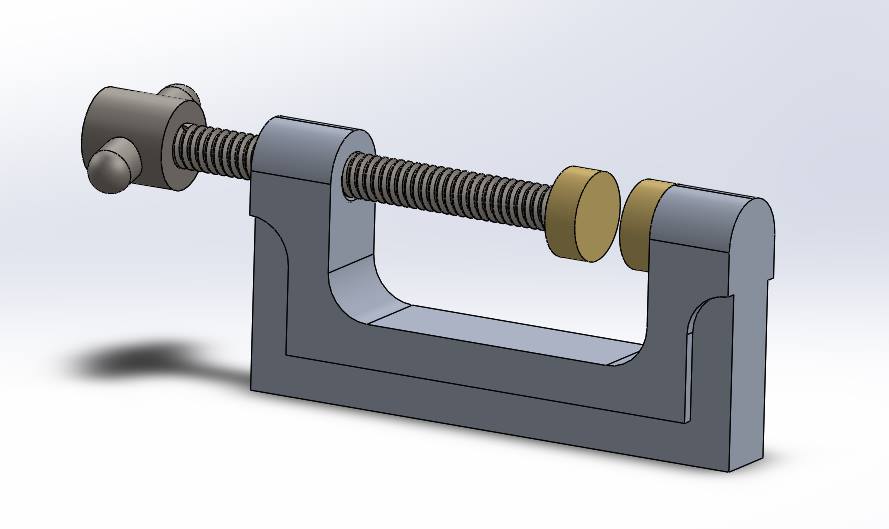

Although I'd like to get onto milling the business card parts, I did want to get a little more practice. They had some more plans for another project that a lot of people in the machine shop build, which is a little C clamp. It includes multiple parts that have to be machined on the mill and lathe. For some more practice translating drawings into 3D models, I put it into Solidworks.

I got pretty far into making the main body of the clamp before realizing I'd like to get going with the business card. So I've stopped working on it for now. Machining the clamp taught me how to think about the ordering of cuts and how to strategize how the part will be clamped.

If anyone is looking for some interesting/educational videos regarding machining, I'd recommend (in no particular order), This Old Tony, Abom79, Clickspring, NYC CNC, Keith Fenner, and Suburban Tool Inc, to name a few.